Unmatched Precision and Accuracy in Laser Cutting

How Laser Cutting Achieves High Precision and Accuracy

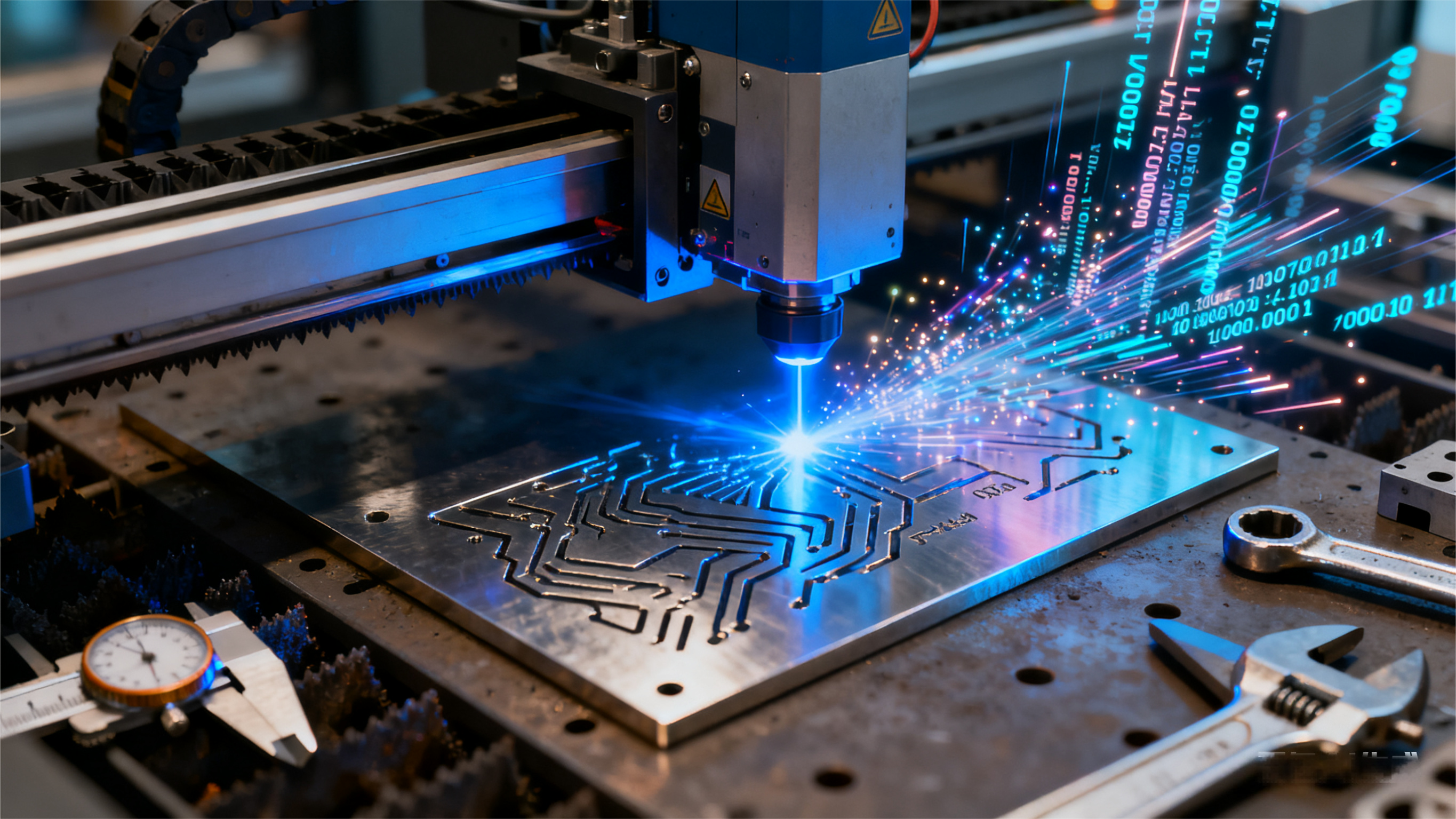

Laser cutting machines work by focusing intense light beams through CNC systems, allowing for incredibly precise cuts at the micron level. According to a recent 2024 study on material processing, these laser systems can keep kerf widths below 0.001 inches or about 0.025 millimeters, while maintaining positional accuracy down to just 5 micrometers. To put that into perspective, this is roughly one fifth the thickness of a single strand of human hair. What makes lasers so special compared to traditional mechanical cutting tools? Well, since there's no physical contact between the tool and material, we avoid all sorts of warping and deformation issues. This means manufacturers get consistently good results whether they're working with metal sheets, plastic components, or composite materials for aerospace applications.

Advantages of Extreme Precision in High-Tolerance Projects

Industries requiring tolerances below ±0.005 inches, such as aerospace and medical device manufacturing, benefit from laser cutting’s repeatability. For example, a semiconductor equipment manufacturer reduced calibration errors by 72% after adopting laser-cut components, illustrating its impact on mission-critical assemblies.

Case Study: Improved Edge Quality in Aerospace Components

Aerospace suppliers report 30% fewer post-processing steps when using laser cutting for turbine blade slots. The method’s narrow heat-affected zone prevents warping in aluminum alloys, while <0.0008-inch edge roughness meets AS9100 aerospace standards for airflow-critical parts.

Comparison with Traditional Cutting Methods in Dimensional Accuracy

| Method | Tolerance Range | Edge Roughness | Post-Processing Required |

|---|---|---|---|

| Laser Cutting | ±0.0005 inches | 12–25 µin | None |

| Plasma Cutting | ±0.020 inches | 150–300 µin | Grinding/Deburring |

| Waterjet Cutting | ±0.005 inches | 50–120 µin | Light Sanding |

Data shows laser cutting outperforms traditional methods, particularly in stainless steel fabrication where 94% of parts meet ISO 2768 fine tolerance grades without secondary operations.

Role of CNC Integration in Maintaining Precision and Consistency

Advanced CNC-driven laser systems automatically adjust beam intensity and cutting speed using real-time sensors. This integration reduces human error, maintaining ±0.002-inch consistency across 10,000-unit production batches—a critical factor for automotive manufacturers implementing Industry 4.0 practices.

Material Versatility and Industrial Adaptability

Compatibility of Laser Cutting Machines With Metals, Plastics, and Composites

Laser cutting systems process over 25 material types with precision, including stainless steel (0.5–25 mm thickness), aluminum alloys, ABS plastics, and carbon-fiber composites. Unlike mechanical cutting tools, laser beams maintain clean edges on thermally sensitive polymers while achieving ±0.1 mm tolerances in aerospace-grade titanium.

Adaptability Across Automotive, Medical, and Aerospace Manufacturing

A 2023 industrial survey revealed 84% of automotive suppliers use laser cutting for lightweight chassis components, while medical device manufacturers apply the technology for sterilizable surgical tool production. This cross-sector flexibility stems from programmable wavelength adjustments—fiber lasers dominate metal fabrication, while CO₂ variants excel in acrylics and polycarbonates.

Case Study: Laser Cutting in Automotive vs. Medical Device Production

A tier-1 auto parts supplier reduced sheet metal waste by 18% after adopting 6 kW fiber lasers, while a medical equipment maker achieved ISO 13485 compliance by cutting nitinol stents with 30 µm accuracy. Both cases highlight how software-driven parameter presets enable rapid industry-specific reconfiguration without hardware changes.

Handling Reflective, Brittle, and Thick-to-Thin Material Challenges

The latest pulsed laser technology helps tackle those annoying reflectivity problems that come up when working with copper and brass materials, which stops the laser beam from bouncing off at dangerous angles. When it comes to fragile stuff like ceramics and glass, laser scribing without physical contact cuts down on tiny cracks forming inside the material. Some tests show this method creates about 40% fewer micro fractures than traditional water jet cutting does. These days, most advanced laser systems can sense when they need to switch from thin aluminum sheets just 0.8 mm thick to much thicker steel plates measuring around 12 mm. The machines handle all sorts of adjustments automatically adjusting focus points and changing gas flow rates as needed during these transitions in the same production run.

Speed, Efficiency, and Production Throughput

Faster Cycle Times in High-Volume Manufacturing Environments

Laser cutting machines excel in high-volume production due to non-contact processing and automated material handling systems. Unlike mechanical cutting tools that require frequent blade replacements, laser systems maintain consistent speeds across 24/7 operations—automotive manufacturers can process over 500 sheet metal parts per hour without downtime for tool adjustments.

Data Point: 30% Faster Than Plasma Cutting With Consistent Quality

A 2024 production analysis found laser cutting machines complete tasks 30% faster than plasma systems while maintaining ±0.1mm accuracy. This speed-quality balance allows aerospace suppliers to meet tight deadlines without compromising compliance with AS9100 aerospace standards.

Impact on Just-in-Time (JIT) and Lean Manufacturing Models

By reducing average part completion times to under 90 seconds, laser technology synchronizes perfectly with JIT workflows. This capability proves vital for lean manufacturing, enabling 18% lower inventory costs through optimized production schedules.

Trend: Automation and Software Integration Boosting Operational Throughput

Recent advancements in IoT-enabled laser cutters demonstrate how real-time monitoring systems increase throughput by 22% in packaging machinery production lines. Operators now achieve 95% operational uptime through predictive maintenance algorithms that preemptively adjust cutting parameters based on material batch variations.

Reduced Waste, Lower Costs, and Environmental Benefits

Higher Sheet Utilization Through Precise Kerf Control

Laser cutting machines achieve 20–30% higher material efficiency than mechanical cutting tools by maintaining kerf widths as narrow as 0.1 mm. This precision eliminates the need for secondary trimming operations, allowing manufacturers to optimize sheet layouts for complex part geometries without compromising structural integrity.

Improved Material Yields and Reduced Scrap Rates

The non-contact nature of laser systems reduces material warping and contamination, enabling high-tolerance manufacturing with 98% first-pass yield rates in electronics applications. A 2023 stainless steel fabrication study showed a 42% scrap reduction compared to plasma cutting, directly lowering raw material purchase costs and waste disposal fees.

Case Study: Waste Reduction in Stainless Steel Fabrication

A leading industrial supplier achieved 37% annual savings in material costs by switching to fiber laser cutting for surgical instrument components. The technology’s 0.05 mm positioning repeatability eliminated edge grinding steps while maintaining ±0.1 mm dimensional accuracy across 15,000 units.

Cost Savings and Sustainability From Minimized Post-Processing and Scrap

By reducing post-processing labor and energy consumption, manufacturers report $18–$22 per-square-meter savings in large-scale architectural metal projects. Closed-loop filtration systems in modern laser cutters recycle 95% of cutting gases and capture 99.6% of particulates, aligning with ISO 14001 environmental management standards.

Design Flexibility and Operational Cost Savings

Enabling Complex Geometries and Intricate Detailing with Laser Precision

Modern laser cutting machines produce features with ±0.1 mm tolerance, enabling fractal-like patterns and organic shapes unachievable with mechanical tools. This capability directly benefits industries requiring micro-perforations (medical filters) or decorative metalwork (luxury architectural panels), where manual methods cause irregular edges.

Software-Driven Adaptability for Rapid Prototyping and Customization

CAD/CAM integration allows manufacturers to pivot between jobs in minutes—a 2023 survey showed 78% of adopters reduced design-to-production time by 40%. Unlike fixed die systems, digital templates accommodate last-minute client revisions without costly tooling reworks.

Elimination of Physical Tooling Reduces Setup Time and Maintenance Costs

Laser systems eliminate $15k–$50k in perishable tooling expenses per production line annually. A stainless steel fabricator reported 62% lower year-over-year maintenance costs after switching from punch presses to fiber lasers.

Quick Digital Job Changeover Enhancing Production Agility

Operators switch between 2D and 3D cutting profiles via cloud-based presets, achieving <15-minute changeovers versus 4–8 hours for conventional retooling. This supports mixed-volume orders—92% of manufacturers using this feature met under-72-hour turnaround demands in a 2024 industrial survey.

Frequently Asked Questions

What is laser cutting?

Laser cutting is a technology that uses focused light beams to make precise cuts through a variety of materials. It operates through CNC systems to achieve high precision without physical contact with the material being cut.

How does laser cutting ensure high precision?

Laser cutting ensures high precision by using intense light beams that focus on micron-level cuts, maintaining kerf widths below 0.001 inches and positional accuracy as fine as 5 micrometers.

What materials can be processed with laser cutting?

Laser cutting can process over 25 types of materials, including metals like stainless steel and aluminum alloys, ABS plastics, carbon-fiber composites, and even aerospace-grade titanium.

How does laser cutting reduce waste and costs?

Laser cutting reduces waste and costs by maintaining precise kerf widths, which reduces scrap rates and post-processing labor. It also increases sheet utilization and lowers raw material purchase costs.

What industries benefit the most from laser cutting?

Industries like aerospace, automotive, and medical device manufacturing benefit the most from laser cutting due to its precision, adaptability, and cost-effectiveness.

Table of Contents

-

Unmatched Precision and Accuracy in Laser Cutting

- How Laser Cutting Achieves High Precision and Accuracy

- Advantages of Extreme Precision in High-Tolerance Projects

- Case Study: Improved Edge Quality in Aerospace Components

- Comparison with Traditional Cutting Methods in Dimensional Accuracy

- Role of CNC Integration in Maintaining Precision and Consistency

- Material Versatility and Industrial Adaptability

- Speed, Efficiency, and Production Throughput

- Reduced Waste, Lower Costs, and Environmental Benefits

- Design Flexibility and Operational Cost Savings

- Frequently Asked Questions