The Science Behind Laser Engraving: From Light to Heat Conversion

Understanding Energy Transformation in Laser Engraving

Laser engraving machines work by turning light energy into heat through something called stimulated emission, which explains why lasers have "SE" in their name. Inside these machines, a laser diode creates light waves that line up just right, concentrating energy at levels around 100,000 times stronger than regular sunlight. When this intense beam hits materials, it can push temperatures up between 500 and 3,000 degrees Celsius almost instantly, causing materials to change states right before our eyes. How efficient this process is depends on what kind of laser we're talking about, usually somewhere between 10% and 30%. Some newer models even manage to capture leftover heat through special liquid cooling systems, making them a bit more environmentally friendly than older versions.

Laser Beam Generation, Focusing, and Material Interaction

Three optical components shape the engraving process:

- Resonator: Amplifies light by reflecting photons between mirrors

- Beam expander: Increases beam diameter for tighter focus

- F-theta lens: Focuses the beam to a spot size of 0.05-0.2 mm

At the focal point, power density reaches 10-10¹¹ W/m²—equivalent to concentrating a stadium's worth of light onto a pinhead. This intensity drives material-specific interactions:

| Interaction Type | Materials Affected | Temperature Threshold |

|---|---|---|

| Vaporization | Wood, acrylic | 150-300°C |

| Melting | Metals, glass | 600-1,400°C |

| Ablation | Painted surfaces | 200-500°C |

How Materials React to Laser Heat: Vaporization, Melting, and Ablation

The amount of energy needed for metal processing is pretty substantial because metals conduct heat so well. Take aluminum for instance; it actually turns into vapor at around 2327 degrees Celsius while zinc only needs about 906 degrees to do the same thing. When we look at polymers, things get interesting too. These materials start breaking down when temperatures reach between 300 and 500 degrees Celsius, which creates those dark spots we often see on surfaces from localized burning effects. For materials that are sensitive to heat such as leather, manufacturers have turned to pulsed laser technology. These lasers deliver short bursts of energy lasting anywhere from 50 to 200 nanoseconds, keeping the heat impact extremely limited to approximately half a millimeter spread. Some cutting-edge equipment now combines two different laser wavelengths, specifically 1064 nanometers and 355 nanometers, allowing both engraving and surface treatment of stainless steel at the same time. This technique produces nice color variations on the metal surface without causing any actual damage to it, something many industrial users find particularly valuable for quality control purposes.

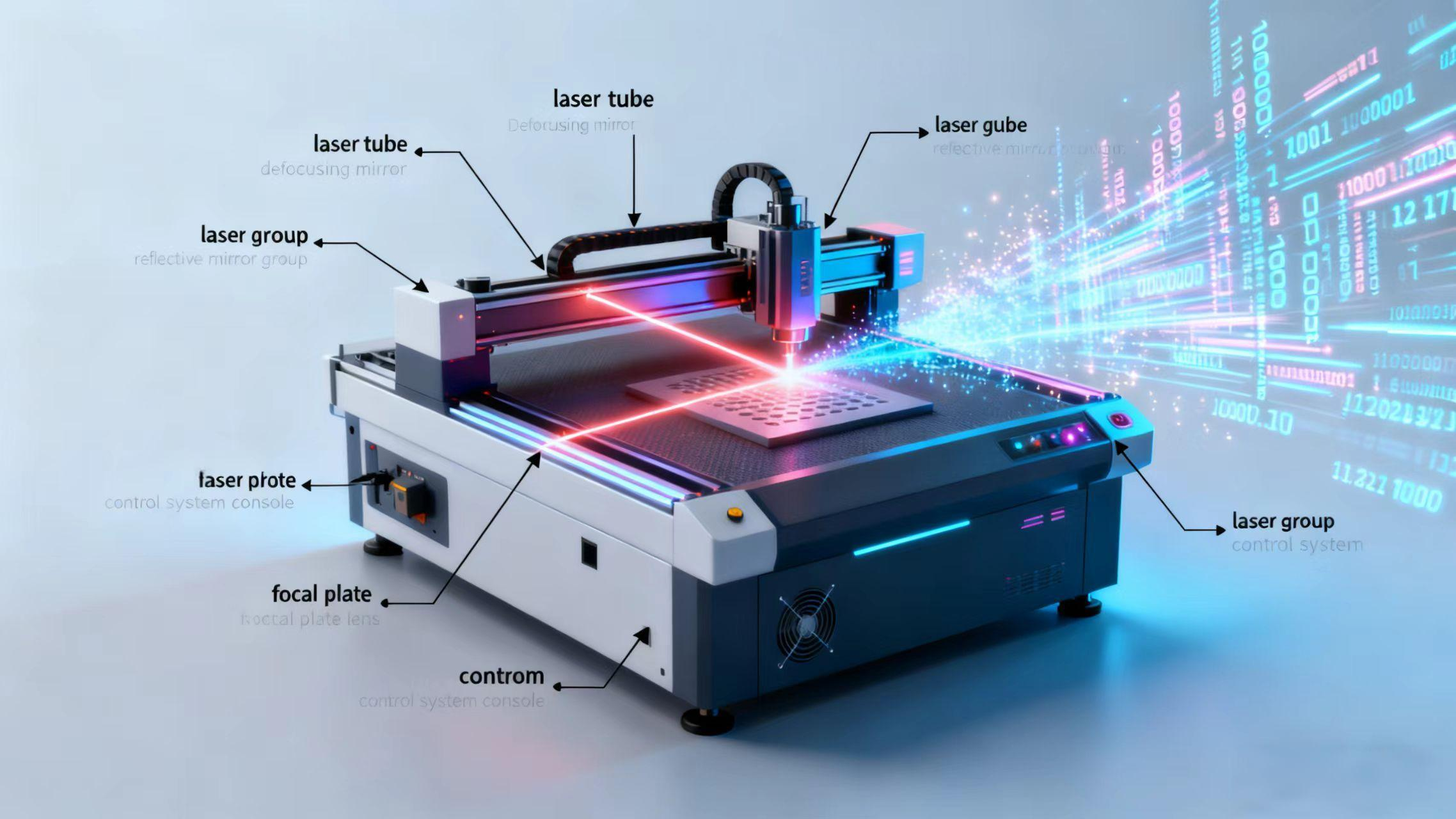

Key Components of a Laser Engraving Machine

Optical System: Lenses, Mirrors, and Beam Delivery

Laser systems work by directing and focusing light energy down to incredibly small areas, often at the micron level. Germanium lenses of exceptional purity handle those tiny beams, sometimes as narrow as less than a tenth of a millimeter across. The mirrors used are coated with gold which reflects over 99% of what hits them, cutting down on wasted energy during operation. Together these parts create clean cuts and detailed engravings when working with materials such as acrylic sheets or surfaces treated with anodization processes. Over recent years there's been progress in how lasers deliver their power too. Manufacturers report around an 18 percent drop in wasted electricity since older versions of these systems were first introduced back in the early 2000s.

Motion Control System: CNC and XYZ Axis Precision

Modern CNC systems guide laser heads with positioning accuracy within 5 μm using servo-driven XYZ axes. This enables flawless reproduction of complex vector designs—from micro-text on surgical tools to large-format signage. Industrial machines often include linear encoders for real-time feedback, correcting positional errors at speeds up to 10,000 mm/min.

Laser Source and Cooling Mechanisms for Stable Operation

What kind of laser we're talking about really determines what it can do. CO2 lasers work great on things like wood, plastic, and other organic stuff because their wavelength sits around 10.6 microns. Fiber lasers, which have a shorter wavelength at about 1.06 microns, are the go-to choice when working with metals, especially for engraving tasks. When it comes to industrial setups, most systems need at least 100 watts of power to handle stainless steel etching properly. Desktop models usually run around 30 watts and handle lighter materials like acrylics and softer woods without issue. Keeping these machines running smoothly requires active cooling solutions. Many shops invest in closed-loop chillers that keep temperatures stable within just plus or minus one degree Celsius. This kind of temperature control prevents those annoying power dips that mess up the quality of marks and engravings. The difference in cooling methods makes a big impact over time too. Lasers that get proper cooling tend to last about 40 percent longer than ones relying only on passive cooling methods, which means fewer replacements and lower long-term costs for manufacturers.

Types of Lasers in Engraving: CO2, Fiber, UV, and MOPA

CO2, Fiber, and Diode Lasers: Applications and Differences

Carbon dioxide lasers operating at around 10.6 microns work really well on things like wood, acrylic sheets, and leather products which people often need cut or engraved for signs and various craft projects. Then there are fiber lasers with that 1,064 nanometer wavelength that create those sharp contrast marks right onto metal surfaces such as stainless steel and aluminum without damaging the material itself. For folks just starting out or working on smaller-scale operations, diode lasers tend to be the go-to option since they handle most plastics and some coated metals while using less electricity overall. According to a recent market analysis from Telesis in 2025, these fiber laser systems now make up about two-thirds of all industrial marking equipment installed across factories worldwide because they last so long - over 100 thousand hours typically before needing replacement.

Fiber Lasers for Metal Engraving and Industrial Use

Fiber laser engraving systems achieve peak performance on metals through photothermal reactions. Their solid-state design enables faster processing (up to 7 m/s) and finer detail (<20 μm line width) than CO2 systems. Key applications include:

- Automotive part serialization

- Medical device UDI compliance marks

- Aerospace component traceability

UV and MOPA Lasers for Precision and Heat-Sensitive Materials

UV lasers (355 nm) enable cold marking by chemically altering surfaces on glass, polymers, and semiconductors without thermal distortion—essential for microelectronics and food packaging. MOPA (Master Oscillator Power Amplifier) fiber lasers offer 16.7 million programmable pulse variations, enabling precise color marking on anodized aluminum and titanium.

Wavelength and Material Compatibility Across Laser Types

| Laser Type | Wavelength | Key Materials | Engraving Depth |

|---|---|---|---|

| CO2 | 10.6 μm | Wood, acrylic | 0.1-5 mm |

| Fiber | 1,064 nm | Metals, plastics | 0.01-0.5 mm |

| UV | 355 nm | Glass, PCBs | <0.1 mm |

Data from a 2025 material compatibility study (Omtech) confirms wavelength directly affects absorption rates—CO2 systems achieve 98% absorption in cellulose-based materials, while UV lasers penetrate 85% deeper in polycarbonate than infrared alternatives.

The Laser Engraving Workflow: From Digital Design to Finished Mark

Design Preparation and Vector Path Generation in Software

Most projects kick off on screen with digital designs created in vector software such as CorelDRAW or Adobe Illustrator. What these programs do is translate pictures into mathematical lines and curves that tell the laser where to go, which means we can get really accurate cuts at around 0.1mm precision. Vector files are generally preferred over regular bitmap images because they don't lose quality when resized, though sometimes people still end up with blurry results if they're not careful. Take logo work for instance, those detailed corporate emblems rely heavily on Bézier curves to maintain sharp corners and smooth transitions between elements. According to some industry reports, roughly 8 out of 10 engraving problems actually come from bad vector path optimization, so spending extra time cleaning up files before sending them to production makes all the difference in avoiding costly mistakes later on.

Transferring Designs to CNC Control Systems

Once the design work is done, most people export their creations as either .DXF or .AI files before loading them onto the CNC machine. These days, machines usually accept transfers via USB sticks or over networks, though bigger operations tend to hook everything up to CAD/CAM systems so they can automate most of the workflow. What happens next? Well, the CNC controller takes those coordinate points and movement instructions and converts them into actual X-Y movements on the machine bed. Getting this right matters a lot because if the laser's focal point isn't properly aligned with the material surface, even something as small as half a millimeter off can really mess things up, cutting clarity down by around two-thirds according to what many technicians have seen in their workshops.

Adjusting Laser Parameters: Speed, Power, and Pulse Frequency

Optimizing settings is crucial for material-specific results:

| Material | Power (Watts) | Speed (mm/s) | Frequency (kHz) |

|---|---|---|---|

| Anodized Aluminum | 30 | 1200 | 20 |

| Acrylic | 15 | 800 | 5 |

| Stainless Steel | 100 | 400 | 50 |

When working with higher power settings around 80 to 150 watts, most metals simply burn away rather than melt properly. On the other hand, those lower power ranges between 10 and 30 watts work much better for plastics and synthetic materials, allowing them to be carefully removed without damaging surrounding areas. Going too slow when engraving into wooden surfaces does create deeper impressions, but this comes at a cost as many hardwoods will start to char or even catch fire if exposed to heat for too long. The pulse frequency setting determines how often energy is delivered during operation. For best results on metal surfaces with protective coatings, most professionals stick to frequencies somewhere between 20 and 50 kilohertz. Modern machines come equipped with sophisticated control panels that let technicians adjust parameters on the fly. These real-time adjustments help find that sweet spot where detailed work gets done without sacrificing production speed, something every workshop manager appreciates when trying to meet tight deadlines.

Material Compatibility and Applications of Laser Engraving Machines

The compatibility between materials and lasers plays a big role in whether engraving works well or not since different surfaces react differently to various wavelengths and power settings. For instance, stainless steel takes in the energy from fiber lasers around 1064 nanometers through what's called localized oxidation, which leaves behind strong industrial markings that last a long time. On the flip side, CO2 lasers operating at about 10.6 micrometers actually burn away the cellulose in wood to create those dark carbonized patterns we see on wooden products. When it comes to glass work, UV lasers can get really detailed, sometimes under half a millimeter accuracy, because they cause tiny cracks beneath the surface. This kind of precision matters a lot in medical device labeling where clarity and permanence are absolutely essential requirements.

| Material | Reaction Mechanism | Laser Type | Application Example |

|---|---|---|---|

| Anodized Aluminum | Color Change | Fiber | Electronic Part Serialization |

| Acrylic | Polished Melting | CO2 | Retail Display Manufacturing |

| Oak | Pyrolysis | CO2 | Architectural Woodworking |

| Tempered Glass | Micro-Fracturing | UV | Laboratory Equipment Marking |

Non-metallic materials like ABS plastics require careful power calibration to avoid toxic fume release, a key consideration in industrial safety standards. The interplay between material reflectivity and thermal conductivity dictates application success, enabling uses ranging from jewelry personalization to aerospace traceability when properly configured.

FAQ

What is laser engraving and how does it work?

Laser engraving is a technology that uses focused light to burn images or designs onto materials. It works by converting light energy into heat, which alters the surface of the material.

What types of materials can be engraved with lasers?

Wide variety of materials can be engraved including wood, metals, glass, acrylics, and certain plastics.

What are the different types of lasers used in engraving?

Common types include CO2, fiber, UV, and MOPA lasers, each varying in wavelength, suitable materials, and applications.

How do you choose the right laser type for a specific material?

Choosing the right laser depends on the material's reaction to different wavelengths and power settings; fiber lasers are ideal for metals while CO2 works well on organic materials.

Can laser engraving affect the properties of the material?

It can cause localized changes such as vaporization, melting, or color variations, depending on the material and the laser settings used.

Table of Contents

- The Science Behind Laser Engraving: From Light to Heat Conversion

- Key Components of a Laser Engraving Machine

- Types of Lasers in Engraving: CO2, Fiber, UV, and MOPA

- The Laser Engraving Workflow: From Digital Design to Finished Mark

- Material Compatibility and Applications of Laser Engraving Machines

- FAQ