Laser Welding Fundamentals: Technology and Process

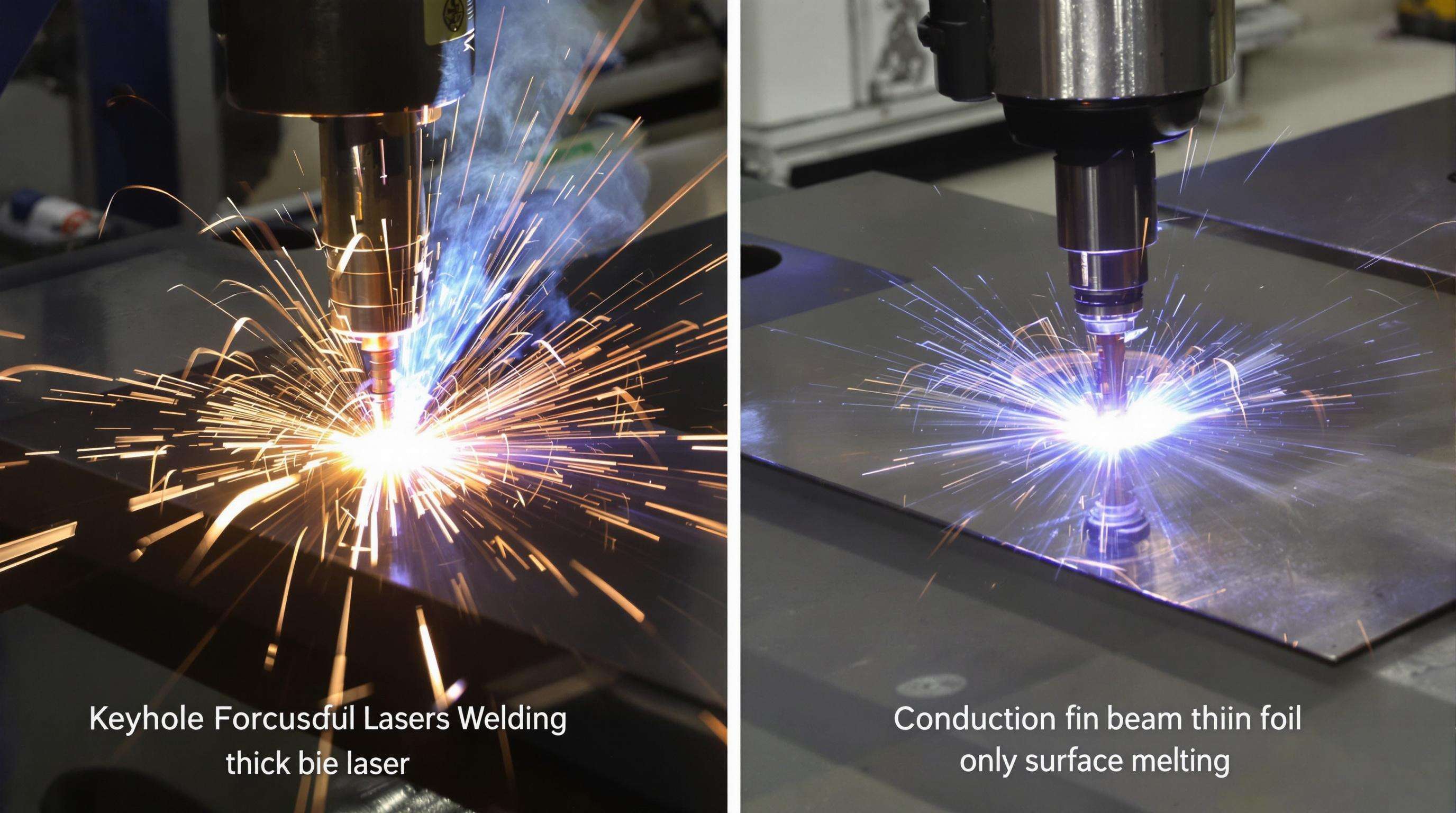

Keyhole vs Conduction Welding Techniques

There are two types of laser welding: keyhole and conduction. Keyhole is drawn out on a workpiece by a high power density beam (â¥1 MW/cm²), melting and vaporizing workpiece material; Keyhole welding has the possibility of deep penetration welding up to 25mm in steel, suitable for thick workpieces. Conduction welds are performed with low power densities (<0.5 MW/cm²) and melt with a solid or liquid surface without vaporizing which is useful for badly fitting seams, thin sections, or with plate edges welded to another surface.

| Factor | Keyhole Welding | Conduction Welding |

|---|---|---|

| Power Density | 1-10 MW/cm² | 0.1-0.5 MW/cm² |

| Penetration Depth | 5-25 mm | 0.1-2 mm |

| Applications | Automotive frames | Electronics, thin foil |

Beam Interaction with Different Metal Alloys

Laser welds are metal dependent because of differences in reflectivity and thermal properties. Its excellent reflectiveness (85-95% at 1µm wavelength) demands 20-30% higher power than with steel. Because of low thermal conductivity of stainless steel, which requires proper heat control in order to prevent it from chromium carbide precipitation. A pulsed beam allows the high thermal shock copper target to be managed and titanium requires inert gas shielding (argon/helium) to avoid oxygen embrittlement.

Essential Parameters: Power, Speed, and Pulse Control

Weld quality hinges on balancing:

- Power: 2-6 kW enables deeper penetration but risks undercutting.

- Speed: Rates above 10 m/min reduce heat but demand tighter beam focus.

- Pulse Control: Pulsing at 50-500 Hz manages heat in dissimilar joints, critical for aerospace aluminum-lithium alloys.

Precision Advantages of Laser Welding Systems

Micro-Welding Capabilities (0.1mm Tolerance)

Laser welding achieves weld seams as narrow as 0.1mm, crucial for medical implants and microelectronics. The beam (<0.5mm diameter) localizes melting, preserving integrity in heat-sensitive assemblies like pacemaker casings. This reduces post-weld machining by 60â80% compared to TIG welding.

Real-Time Monitoring Through Optical Sensors

High-speed cameras and photodiodes track weld pool dynamics at 20,000 frames per second, detecting porosity or incomplete penetration instantly. In aerospace, this reduces defect rates to <0.2% for turbine blade seals. Advanced systems use spectral analysis and machine learning to predict joint strength from plasma plume characteristics.

Laser Welding vs Traditional Fusion Methods

Heat Input Comparison: 30-50% Reduction in Distortion

Laser welding cuts heat input by 60-80% versus arc methods, with a 70% narrower heat-affected zone (HAZ). Automotive manufacturers report 30-50% fewer post-weld fixes in door panels (American Welding Society, 2018).

Case Study: Automotive Body Welding Cycle Time Analysis

A 2025 study showed laser systems reduced chassis cycle times from 45 to 12 minutes. BMW achieved 2,400 welds per vehicle with 0.02mm repeatability.

| Factor | Traditional Welding | Laser Welding | Improvement |

|---|---|---|---|

| Cycle Time/Vehicle | 45 minutes | 12 minutes | 73% faster |

| Energy Consumption | 12 kW | 3.5 kW | 71% savings |

| Post-Processing | Required | Minimal | 85% reduction |

Material Savings Through Narrower Weld Seams

Laser systems achieve 0.8mm seams versus 3mm in arc welding, reducing filler use by 40%. In electronics, this boosts material utilization from 78% to 92%.

Optimizing Laser Welded Joint Strength

Beam Focus Strategies for 10mm+ Thick Metals

For thick sections, oscillating beams improve depth-to-width ratios by 40%. Multi-pass strategies enable 18mm aluminum welds with 95% joint efficiency.

Shielding Gas Selection for Aluminum and Stainless Steel

Argon-helium mixtures (70/30) cut aluminum porosity by 60%. For stainless steel, nitrogen-supplemented shielding (2-4% Nâ) enhances pitting resistance.

Post-Weld Heat Treatment Compatibility

Controlled heating at 450-600°C relieves stress in titanium while preserving 85% of base metal fatigue strength (ASTM E407-22).

Industry-Specific Applications and Solutions

Aerospace: Welding Titanium Fuel Lines

Laser welding achieves 900MPa tensile strength on 3mm-thick titanium at 8m/min, reducing post-weld heat treatment by 70% versus TIG.

Medical Devices: Hermetic Sealing of Implants

Fiber lasers produce 50µm-wide welds with 5µm repeatability, achieving leak rates below 1Ã10â»â¹ mbar·L/s for pacemaker housings.

Automotive: Battery Tray Welding for EVs

Scanner lasers weld aluminum trays at 120mm/ms, cutting thermal distortion by 60% and saving 18% material per chassis.

FAQ Section

What types of materials are suitable for laser welding?

Laser welding works with a variety of metals such as steel, aluminum, titanium, and copper, though the reflectivity and thermal properties of the metal can affect the process.

How does laser welding compare to traditional methods?

Laser welding offers reduced heat input, narrower heat-affected zones, and less post-processing compared to traditional fusion methods, enhancing precision and efficiency.

What are the real-time monitoring capabilities in laser welding?

Advanced systems equipped with optical sensors track weld pool dynamics, using high-speed cameras and photodiodes to instantly detect defects.