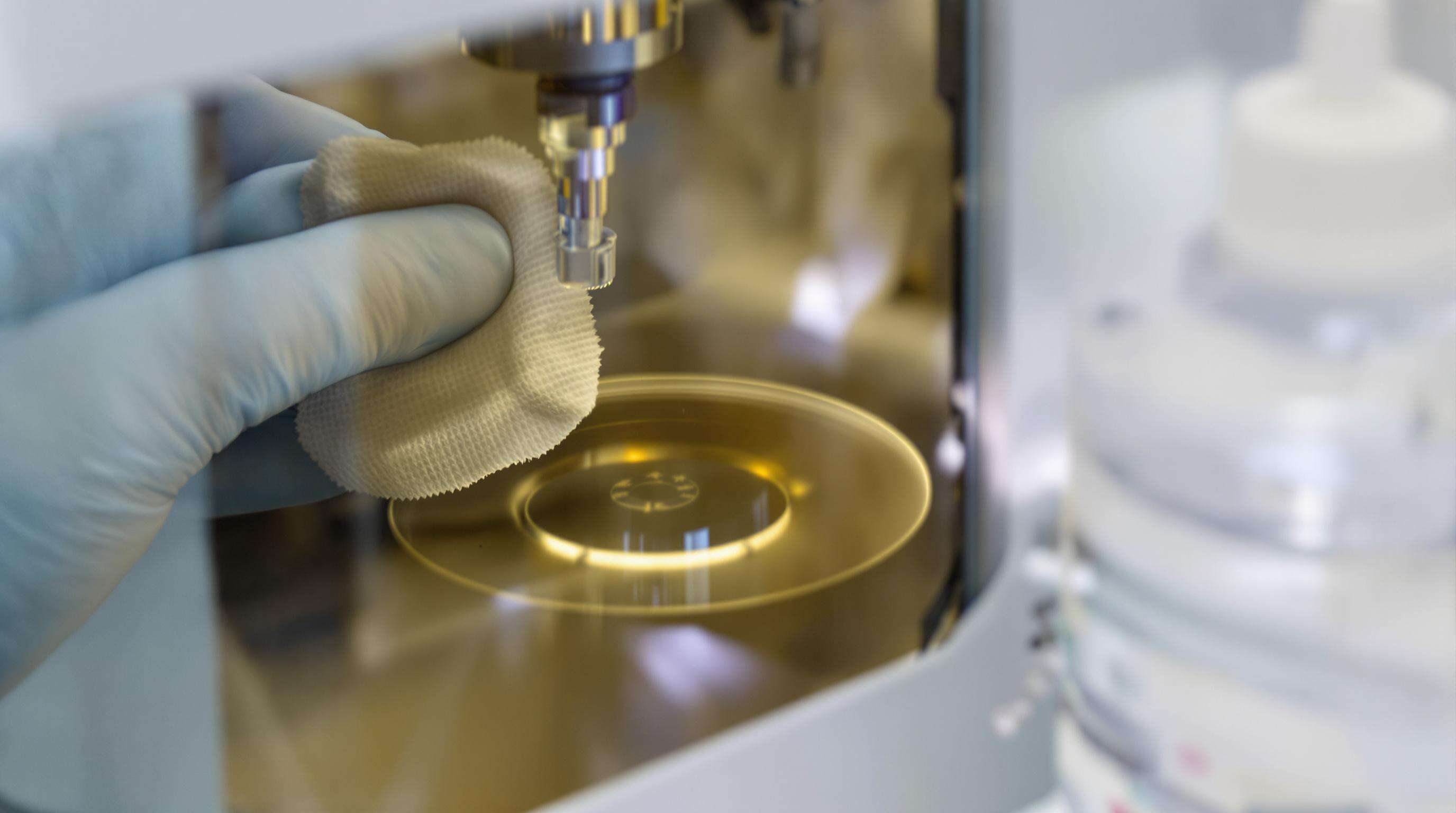

Optical Surface Maintenance Techniques

Clean optical surfaces daily using lint-free wipes and 90%+ isopropyl alcohol to prevent residue buildup. Avoid paper towels or abrasive materials—a single 0.1 mm scratch can reduce beam focus accuracy by 18% (Laser Systems Journal 2023). Inspect under angled lighting to detect contaminants missed by straight-on views.

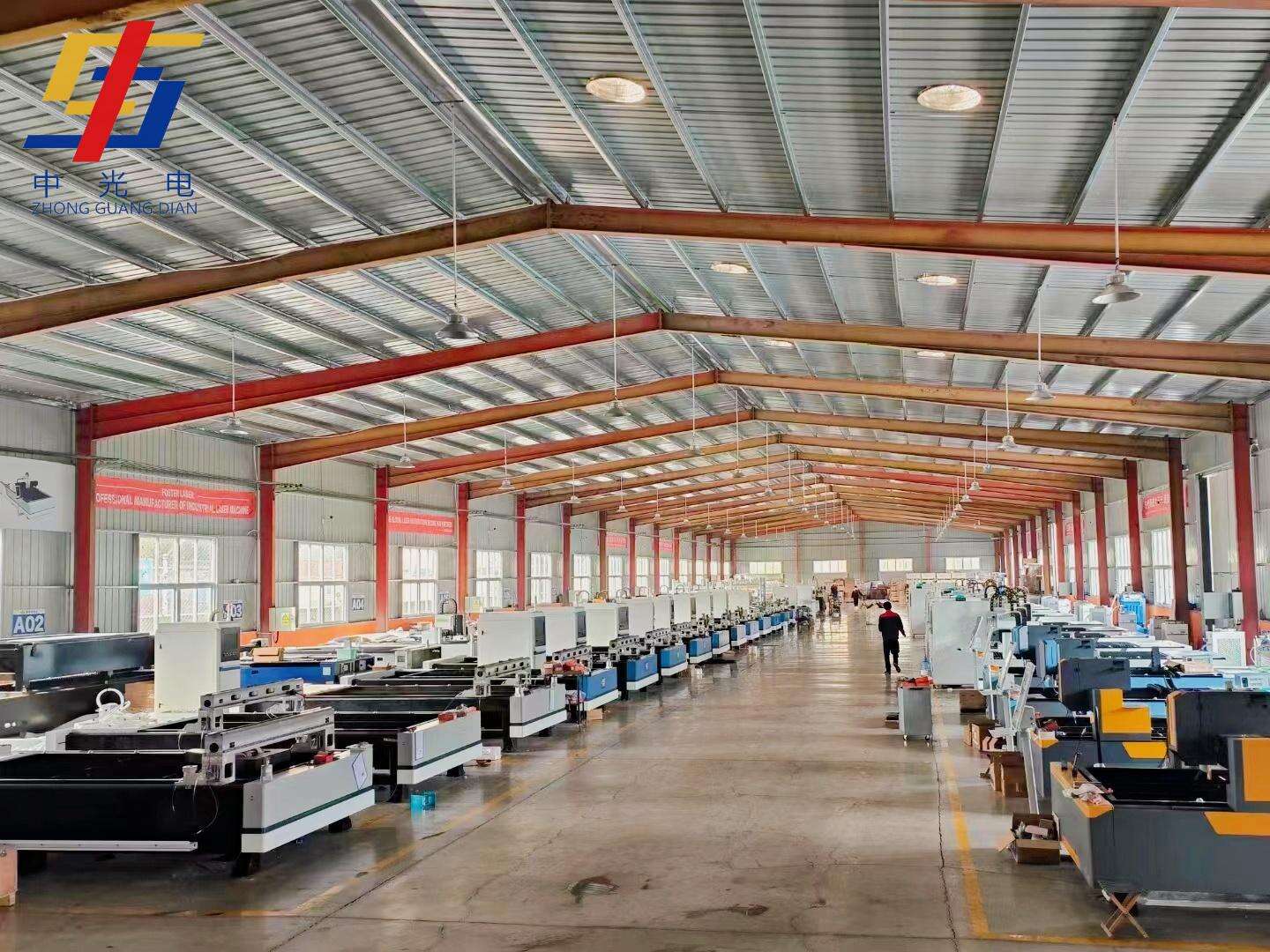

Debris Removal from Cutting/Engraving Beds

Vacuum engraving beds after each job using HEPA-filter systems. For sticky residues, apply non-flammable solvents sparingly to avoid calibration issues. Left unchecked, debris increases refocusing cycles by 22% and accelerates nozzle wear.

Lubrication of Mechanical Components

Apply manufacturer-specified lubricants to:

- Linear rails: Silicone-based grease every 120 operating hours

- Ball screws: High-viscosity oil weekly

- Z-axis gears: Dry PTFE spray monthly

Wipe excess lubricant with microfiber cloths to prevent dust accumulation.

Cooling System Maintenance for Fiber Laser Equipment

Proper cooling extends fiber laser lifespan by 30—40% (Laser Systems Journal 2023).

Radiator Cleaning Cycles

Dust on radiator fins reduces heat dissipation by up to 22%. Use compressed air biweekly, focusing on rear exhaust areas. For stubborn residue, isopropyl alcohol wipes preserve fin integrity.

Coolant Filter Replacement Schedule

Replace inline coolant filters every 400 operating hours or quarterly. Inspect used filters for metallic particles, which indicate bearing wear.

Temperature Monitoring Best Practices

Maintain coolant between 18—22°C with ±0.5°C accuracy sensors. Program automatic shutdowns at 26°C to prevent thermal runaway.

Optics Inspection & Calibration for Metal Cutting Lasers

Lens Alignment Verification Methods

Verify alignment weekly using grid paper tests. Deviations exceeding ±0.05mm reduce cutting efficiency. For industrial systems, laser alignment tools measure accuracy within 5 microns.

Mirror Reflectivity Testing Procedures

Maintain reflectivity above 98% to prevent power loss. Test monthly using photodiode sensors. Gold-coated CO2 mirrors require anhydrous alcohol cleaning to remove oxidation.

Power Supply & Gas Monitoring in CO2 Laser Systems

Gas Purity Level Checks

Use infrared gas analyzers quarterly to detect contamination, which can reduce energy output by 20%. Replenish gases based on usage hours, not calendar dates.

Voltage Stability Maintenance

Voltage instability exceeding ±5% accelerates tube wear. Install dedicated regulators and perform weekly multimeter tests. Real-time monitoring reduces alignment errors by 42%.

Scheduled Maintenance Programs for Welding Lasers

Proactive scheduling reduces downtime by 38% (Ponemon 2024).

Weekly Nozzle Replacement Cycles

Replace nozzles every 7—10 operating hours to maintain gas flow. Carbon buildup exceeding 0.3 mm increases weld porosity risks by 12%.

Annual Laser Tube Inspection

Certified technicians should evaluate tubes, measuring:

| Parameter | Tolerance Range |

|---|---|

| Beam Mode Stability | ±2% deviation |

| Gas Purity | ≥99.995% |

| Cooling Efficiency | ≤3°C variance |

Operator Training for Small Laser Cutting Machines

Training reduces errors by 38% (Industrial Laser Journal 2023).

Error Code Recognition Training

Teach operators to:

- Match error patterns to failures

- Distinguish urgent vs. non-critical alerts

- Reset parameters safely

Emergency Shutdown Protocols

Execute full halts in <8 seconds during emergencies. Steps include sequential powerdown and hazard containment.

Environmental Protection for Laser Marking Equipment

Humidity Control Requirements

Maintain 30—60% RH to prevent condensation or static risks.

Anti-Vibration Setup Configurations

Use vibration isolation pads and conduct monthly resonance tests to maintain <10 µm

FAQ

How often should optical surfaces be cleaned?

Optical surfaces should be cleaned daily using lint-free wipes and isopropyl alcohol.

What is the purpose of vacuuming engraving beds?

Vacuuming engraving beds removes debris to prevent refocusing cycles and accelerates nozzle wear.

How is cooling system maintenance important?

Proper cooling extends laser lifespan by 30—40% and requires regular cleaning and filter replacements.

How can gas purity levels affect CO2 laser systems?

Gas purity contamination can reduce energy output by 20%, so regular checks and replenishment are essential.

Table of Contents

- Optical Surface Maintenance Techniques

- Debris Removal from Cutting/Engraving Beds

- Lubrication of Mechanical Components

- Cooling System Maintenance for Fiber Laser Equipment

- Radiator Cleaning Cycles

- Coolant Filter Replacement Schedule

- Temperature Monitoring Best Practices

- Optics Inspection & Calibration for Metal Cutting Lasers

- Lens Alignment Verification Methods

- Mirror Reflectivity Testing Procedures

- Power Supply & Gas Monitoring in CO2 Laser Systems

- Gas Purity Level Checks

- Voltage Stability Maintenance

- Scheduled Maintenance Programs for Welding Lasers

- Weekly Nozzle Replacement Cycles

- Annual Laser Tube Inspection

- Operator Training for Small Laser Cutting Machines

- Error Code Recognition Training

- Emergency Shutdown Protocols

- Environmental Protection for Laser Marking Equipment

- Humidity Control Requirements

- Anti-Vibration Setup Configurations

- FAQ