Core Laser Technologies That Define High-Performance Laser Marking Machines

Understanding CO2, Fiber, Diode-Pumped, Green, and UV Laser Types

Today's laser marking equipment typically uses one of five main technologies: CO2, fiber, diode pumped, green, and UV lasers. The CO2 variety works best on things like wood and acrylic because of its long wavelength around 10,600nm. Fiber lasers at about 1,064nm are the go-to choice for metals since they pack more punch and get absorbed better by most metals. For materials that don't handle heat well, green lasers at 532nm and especially UV lasers at 355nm shine through. Some tests show UV lasers can absorb up to 98% of energy when working on glass surfaces, way ahead of what infrared lasers manage (check out Laser Tech Journal from last year). When picking the right wavelength, material matters a lot. That explains why companies making airplane parts usually have to decide between CO2 and fiber options when dealing with aluminum parts and those special polymer coatings.

Why MOPA Fiber Lasers Offer Superior Control and Versatility

MOPA lasers, which stands for Master Oscillator Power Amplifier, can adjust their pulse duration anywhere between 4 nanoseconds up to 200 nanoseconds. This adjustment capability gives manufacturers really good control over how deep the marks go into materials, typically ranging from just 0.01 millimeters all the way to 0.5 millimeters. Plus it affects things like oxidation on surfaces too. The range of what these lasers can do is pretty impressive actually. They work great for creating those dark finishes needed on medical instruments after surgery, and they also create very clear markings on stuff like aluminum that's been treated with anodizing processes. According to some research published last year in the industry journals, companies using MOPA systems saw their need for fixing mistakes drop by almost two thirds compared to older fixed pulse laser technology when working with products made from different kinds of materials together.

How Wavelength Affects Marking Quality Across Different Materials

Wavelength determines how laser energy interacts with materials:

- Near-Infrared (1,064nm): Best suited for metals like stainless steel and titanium

- Green (532nm): Reduces heat dispersion in PCB etching

- UV (355nm): Enables cold marking on silicone and PET without melting

Mismatched wavelengths can decrease material absorption by 40–70%, according to ISO 13332:2023 standards, underscoring the importance of alignment between laser type and substrate.

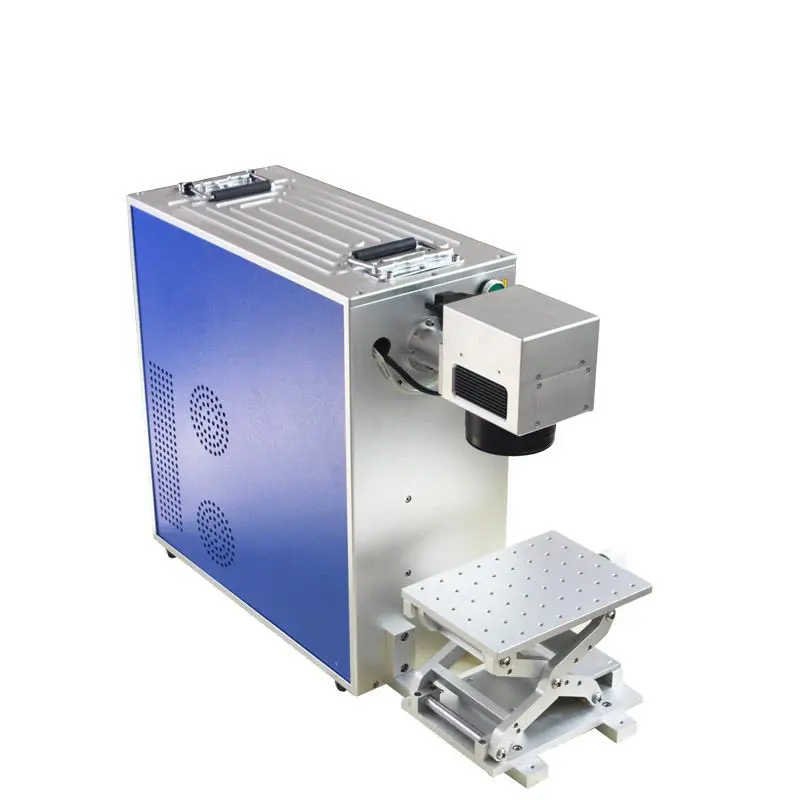

Key Technical Parameters: Laser Power, Scanning Speed, and Resolution

The amount of laser power available, typically ranging from 20 watts to 300 watts, has a direct impact on how fast markings can be made as well as how deep they penetrate materials. Take a 50 watt system for instance. When working with aluminum, it's possible to reach speeds of around 7,000 millimeters per second while still keeping the marking depth at about 0.02 millimeters. Galvo scanners that operate at high speeds, accelerating anywhere between 2,500 and 4,000 mm/s squared, allow for very fine line widths as small as 10 micrometers. These kinds of specifications matter a lot when creating tiny QR codes or unique identification marks. Getting the right balance among all these factors not only cuts down on energy usage by approximately 35 percent but also ensures that the final product meets those strict MIL-STD-130 standards for legibility.

Material Compatibility: How It Determines Precision and Permanence in Laser Marking

Material compatibility forms the foundation of effective laser marking outcomes, directly influencing both mark quality and longevity. Selecting the appropriate laser type for specific substrates prevents surface damage while ensuring legibility—critical for industries requiring permanent identifiers.

Marking Metals, Plastics, and Sensitive Components with the Right Laser Type

Stainless steel works really well with fiber lasers because these machines pack a lot of power into small areas, making them great for etching numbers and letters cleanly without weakening the metal itself. When it comes to plastics though, getting the right laser wavelength matters a lot. Medical devices often get marked with UV lasers at around 355 nanometers since this prevents heat damage that could warp delicate components. For things like plastic packaging materials, companies typically go with CO2 lasers operating at approximately 10.6 microns as they cut through polymers pretty effectively for logo engraving purposes. Some recent research from last year showed something interesting too – if manufacturers pair the wrong type of laser with their material, the resulting marks might only last about 30% as long as they should. That's why many shops now invest time upfront figuring out exactly what kind of setup will work best for each specific job requirement.

The Role of Material Properties in Achieving Durable, High-Contrast Marks

The properties of materials play a big role in determining what works best when it comes to laser settings. Take aluminum for instance, which reflects so much light that it needs extra power compared to those anodized surfaces. Engineered plastics are different though; they work better with certain pulse frequencies otherwise they tend to burn or carbonize during processing. When applied correctly, these fine tuning adjustments can produce markings with contrast ratios over 90 to 1 on stainless steel instruments used in surgery. This meets the requirements set out by the ISO 15223-1 standard for medical device markings, something hospitals and clinics really care about when ensuring proper identification of their equipment.

Case Study: High-Quality Stainless Steel Marking Using Fiber Laser Technology

One manufacturing company recently managed to create aerospace quality markings on their 304 stainless steel components using a 50 watt MOPA fiber laser setup. After fine tuning the settings to around 200 kilohertz pulse frequency and setting the scanning speed at approximately 1500 millimeters per second, they were able to get those really precise marks about 0.1 millimeters deep with line accuracy down to 12 micrometers. These results actually surpassed what's required by the MIL-STD-130N standards for part identification. The improvements made quite a difference too - rework had to be done on roughly 40% fewer parts now, and overall production output climbed all the way up to 1200 parts every single hour.

Precision, Speed, and Quality: The Key Performance Indicators of a Standout Laser Marking Machine

Ensuring Accuracy for Industrial Traceability and Compliance

High-performance laser marking systems achieve positional accuracy within 0.02 mm (ISO 9001:2015), essential for aerospace components requiring permanent identifiers. In medical manufacturing, this precision enables UDI codes with 99.9% scannability (FDAAA 2023), supporting compliance with global traceability regulations.

Optimizing Marking Speed Without Sacrificing Durability or Clarity

The best systems can actually reach speeds around 7,000 characters per second and still produce those clear, lasting marks that everyone wants. What makes these systems stand out is their advanced pulse modulation technology. This helps avoid problems with heat damage when working on delicate materials like thin metal sheets or certain plastics. For car part manufacturers, this means they can mark about 2,000 engine components each hour without compromising how well the zinc alloys resist rust and corrosion. And here's something interesting - even with all this marking going on, the contrast remains pretty good too, hitting at least 20% according to ASTM standards (B487-22) which is actually quite impressive for industrial applications.

Industry Applications and Innovation Trends Driving Laser Marking Machine Advancements

Critical Uses in Automotive, Medical Devices, and Electronics Manufacturing

Laser marking equipment plays really important roles in several industries these days. Car companies rely on fiber lasers to etch those unique VIN numbers onto vehicles plus mark various safety parts too, often achieving around 10 microns of precision according to recent reports from 2024 in laser tech. This kind of accuracy helps meet all sorts of global tracking requirements. When it comes to making medical devices, manufacturers turn to UV lasers instead. These special beams produce markings that won't irritate body tissues while maintaining sterility, which is absolutely necessary if they want their products approved by regulators like the FDA or follow EU Medical Device Regulations. Meanwhile, folks working in electronics manufacturing have their own needs. They use what's called ultrafast diode pumped lasers to put identification marks on circuit boards and even tiny components inside smartphones. Some systems can actually handle upwards of twenty thousand characters per minute, pretty impressive when you think about how small those parts really are.

Growing Demand for UV and Green Lasers in Heat-Sensitive Applications

Strategic Selection: Matching Laser Marking Machine Capabilities to Application Needs

Choosing the right system depends on four key factors:

| Parameter | Automotive Tier 1 Supplier | Medical Device OEM | Electronics Maker |

|---|---|---|---|

| Power Requirement | 50W–100W Fiber | 3W–10W UV | 20W–30W MOPA |

| Marking Speed | 10m/s | 5m/s | 15m/s |

| Regulatory Alignment | IATF 16949 | ISO 13485 | IPC-A-620 |

This strategic alignment explains why automotive leaders integrate MOPA fiber lasers into Industry 4.0 workflows, while medical manufacturers adopt UV systems with <5µm wavelength stability. As automation expands, these tailored pairings have reduced rework costs by 40% in high-volume production environments.

FAQ Section

What are the main types of lasers used in laser marking machines?

The main types of lasers used in laser marking machines are CO2, fiber, diode pumped, green, and UV lasers.

Why are fiber lasers preferred for marking metals?

Fiber lasers, with a wavelength of approximately 1,064nm, are preferred for metals because they pack more power and are better absorbed by metallic surfaces.

How do MOPA fiber lasers differ from other lasers?

MOPA fiber lasers allow for adjustment of pulse durations, providing enhanced control over marking depth and surface effects, thus offering higher versatility compared to fixed pulse lasers.

What industries heavily rely on laser marking technology?

Automotive, medical devices, and electronics manufacturing industries heavily rely on laser marking technology to achieve precision and compliance with global regulations.

Table of Contents

- Core Laser Technologies That Define High-Performance Laser Marking Machines

- Material Compatibility: How It Determines Precision and Permanence in Laser Marking

- Precision, Speed, and Quality: The Key Performance Indicators of a Standout Laser Marking Machine

- Industry Applications and Innovation Trends Driving Laser Marking Machine Advancements

- FAQ Section