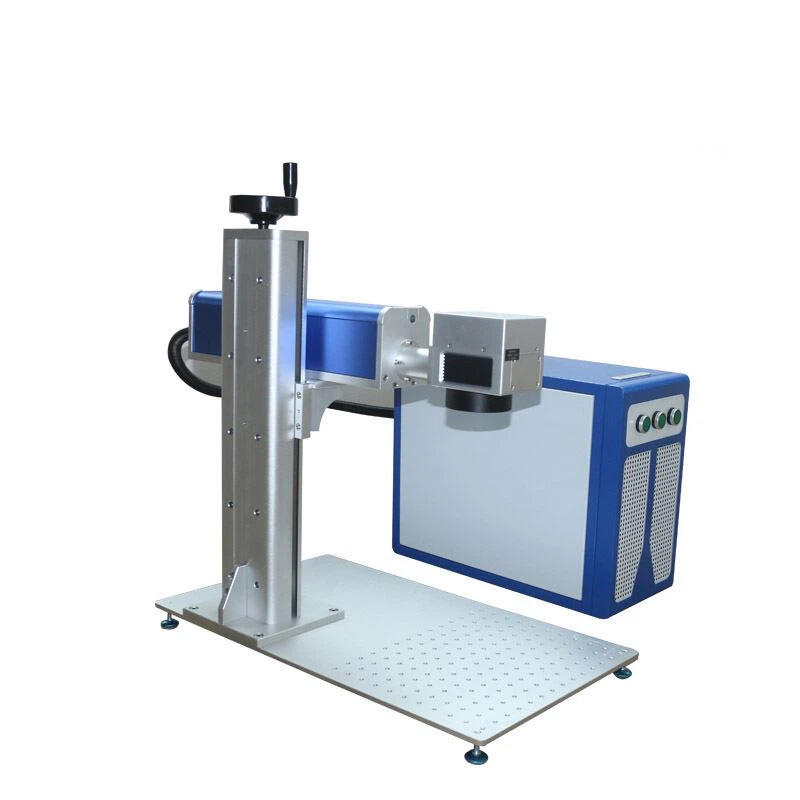

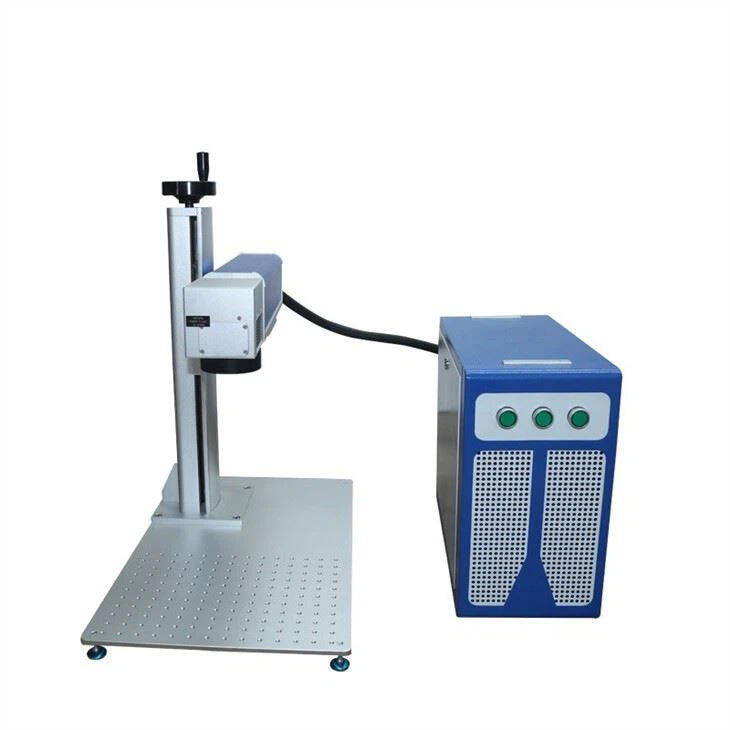

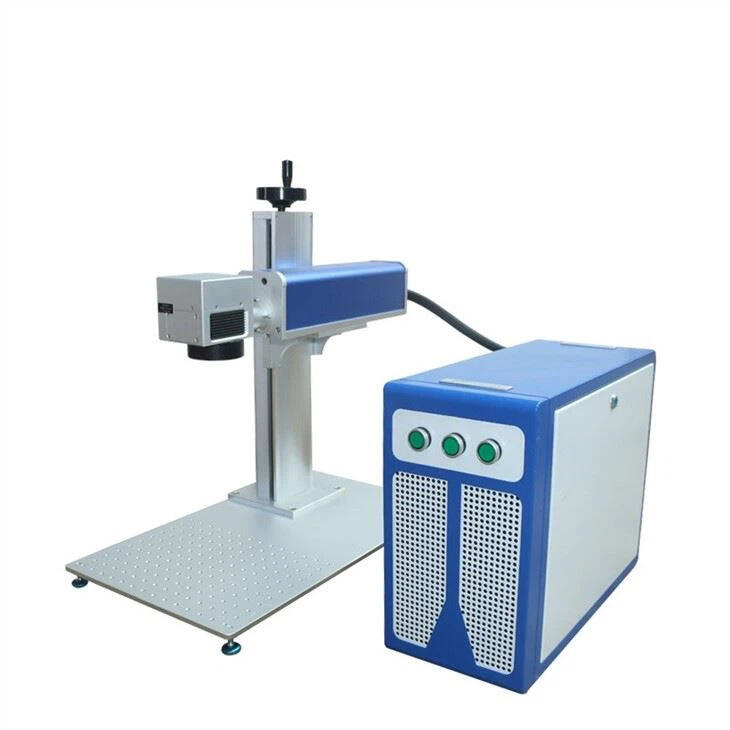

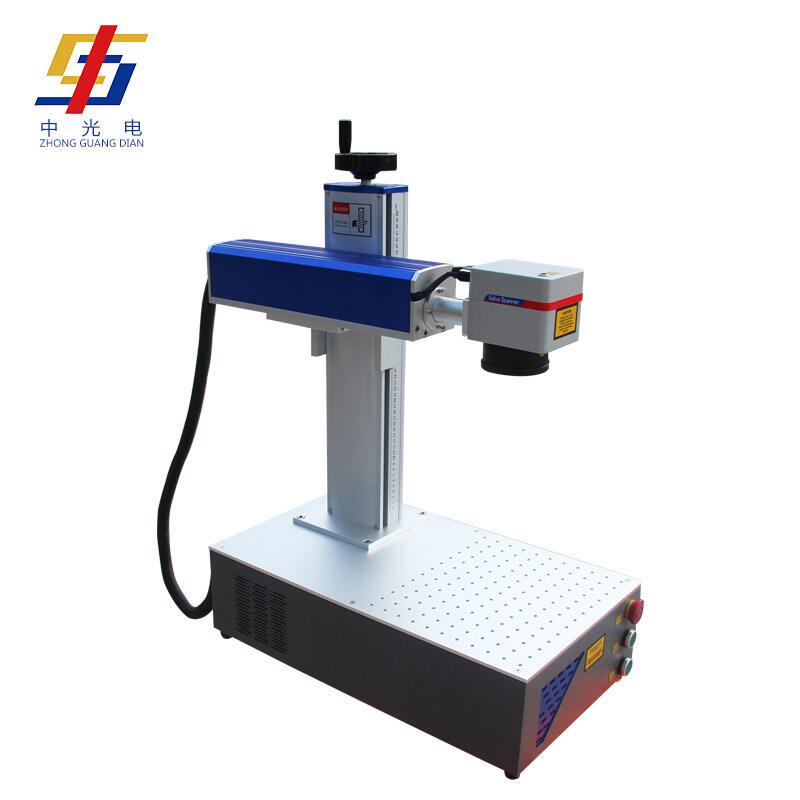

Split Optical Fiber Marking Machine

◆ Split Optical Fiber Marking Machine;

◆ Model: HB Optical Fiber Marking Machine-2;

◆ Laser type: Fiber laser;

◆ Laser power: 20W/30W;

◆ Marking speed:500mm/s;

◆ Working area:110*110mm or 200*200mm.

- Overview

- Related Products

Introduction

The Split Optical Fiber Marking Machine is a specialized device that employs laser technology for high-precision engraving or marking on different materials. It features excellent beam quality, long lifespan, energy efficiency, and low operational costs. By using optical fiber to transmit the laser beam and an advanced computer control system, it enables detailed processing and versatility in marking applications. This machine is widely utilized in industries such as electronics, automotive, and medical to create durable and clear markings on components.

Feature

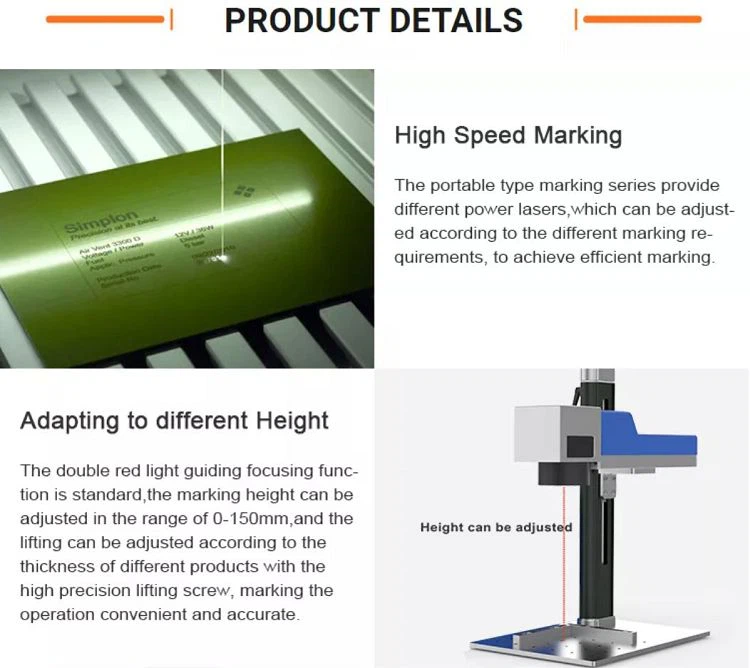

● Adjustable Height for Versatile Marking

The Split Optical Fiber Marking Machine is designed with a column that enables precise adjustments of the laser head's height. This capability is crucial for effectively marking workpieces of different shapes and thicknesses, ensuring high-quality results across a variety of applications.

● High-Quality Laser Beam Emission

Our marking machines incorporate a diode paired with optical fiber for efficient pumping. This advanced design allows the pumping light to effectively propel particles in the opposite direction, producing a high-quality laser beam. The enhanced beam quality improves marking precision, making it ideal for intricate applications.

● Durability in Harsh Environments

Split Optical Fiber Marking Machines are built to function continuously in demanding work conditions. Their sturdy construction guarantees reliability and durability, even in environments that may contain dust, moisture, or extreme temperatures. This robustness minimizes downtime and lowers maintenance costs, making them an excellent option for industrial settings.

● Enhanced Efficiency and Productivity

The synergy between adjustable height and high-quality laser output boosts the efficiency of marking processes. Users can swiftly transition between different workpieces without extensive setup adjustments, conserving valuable time and enhancing overall productivity.

● Cost-Effectiveness

By facilitating efficient marking across various conditions, our Split Optical Fiber Marking Machines contribute to lower operational costs. Their longevity and minimal maintenance needs make them a wise investment for businesses looking for dependable marking solutions.

Applications

1. Electronics Industry

In the electronics sector, Split Optical Fiber Marking Machines play a crucial role in marking serial numbers, barcodes, and logos on components such as circuit boards and semiconductors. For example, manufacturers can engrave unique serial numbers on each item, ensuring traceability throughout the supply chain. This functionality not only aids in tracking the product's lifecycle but also enhances branding by allowing companies to incorporate their logos on essential parts, promoting brand recognition among consumers.

2. Aerospace Industry

The aerospace industry requires precise and durable markings to meet safety and compliance standards. Split Optical Fiber Marking Machines are capable of creating high-quality identifiers on components like turbine blades and avionics systems. These markings are designed to withstand extreme conditions, providing essential information for maintenance and quality control. For instance, part numbers and manufacturing dates can be permanently engraved on aerospace components, ensuring compliance with stringent regulatory requirements and facilitating easy traceability back to their origins.

3. Medical Devices

In the medical field, adherence to strict regulations is critical. Split Optical Fiber Marking Machines enable the marking of identification codes on surgical instruments and medical implants, ensuring compliance with industry standards. For instance, hospitals can use these machines to engrave UDI (Unique Device Identification) codes on implants, improving patient safety by simplifying the tracking of device recalls and verifying authenticity.

4. Automotive Manufacturing

Automotive manufacturers depend on precise markings to improve traceability and ensure quality assurance. Split Optical Fiber Marking Machines can engrave part numbers, production dates, and other essential information on automotive components like engine blocks and brake systems. For example, by marking key components, manufacturers can streamline identification during inspections and maintenance, significantly enhancing the efficiency of the supply chain.

5. Jewelry Industry

In the jewelry industry, ensuring the authenticity and traceability of products is vital for preventing counterfeiting. Split Optical Fiber Marking Machines are utilized to engrave logos, serial numbers, and other identifiers on precious metals and gemstones. This process not only verifies the authenticity of luxury items but also helps maintain a brand's reputation. For instance, a jeweler can engrave a unique serial number on each piece, making it easier for customers to confirm the authenticity and value of their purchases.

Application Materials

Technical Parameters

| Laser Mode | Raycus Fiber Laser Source |

| Wavelength | 1064nm |

| Laser Power | 20W/30W |

| Frequency | 20kHz~100kHz |

| Cooling Way | Forced-air Cooling |

| Marking Speed | ≤3000mm/s |

| Power Stability | ≤0.5% |

| Laser Accuracy | 0.025mm |

| Software | Copyright EzCad |

| File Formats | PLT,PCX, DXP, BMP,JPG etc |

| Working Area | 110x110mm~200x200mm |

| Indicating Beam | Double Red Light Indication |

| Power Supply | 220V/50Hz/2kVA(Customized) |

| Output Compatibility | AutoCAD, CorelDRAW, Photoshop etc |

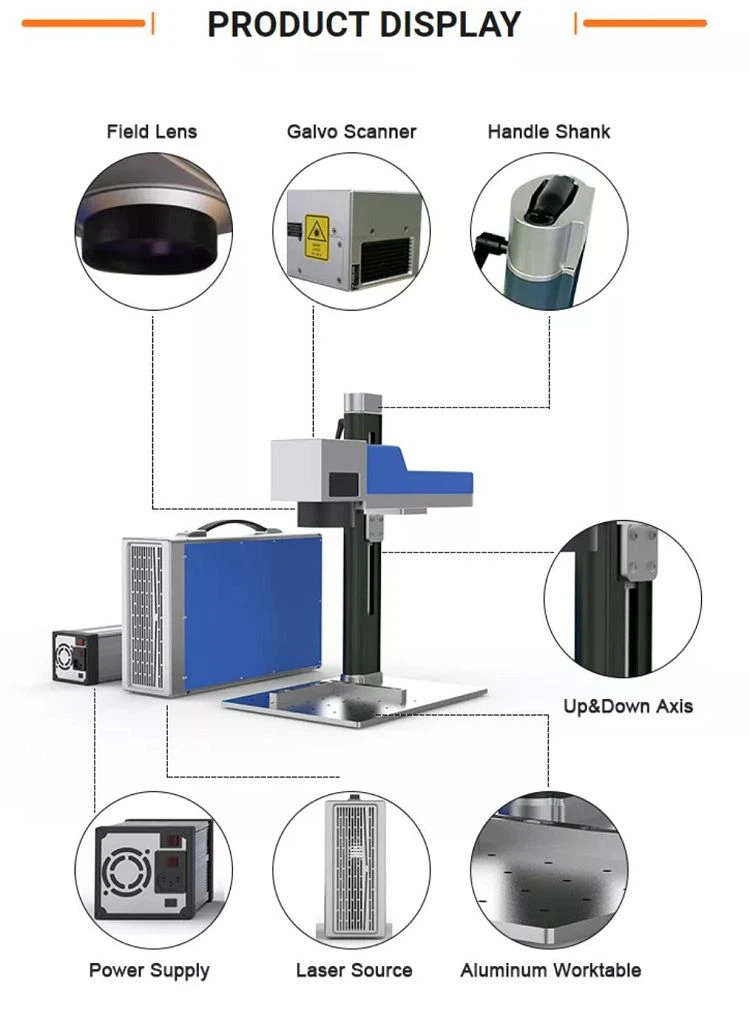

Details

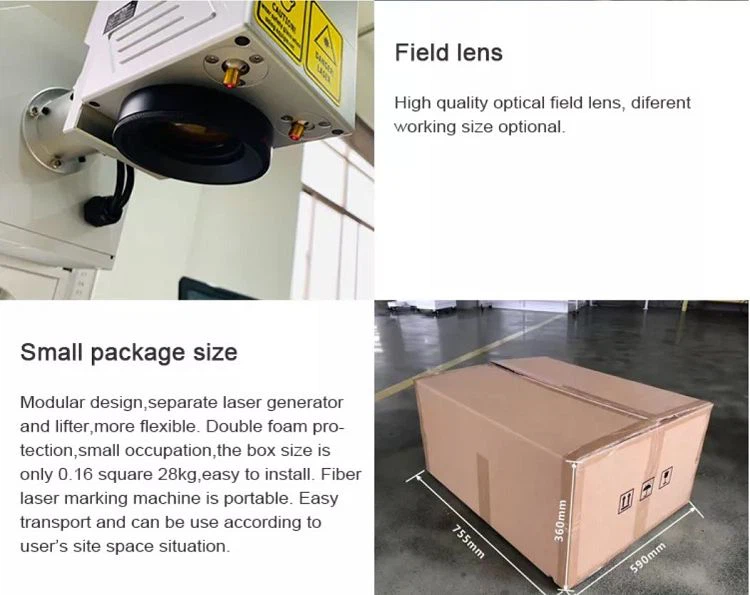

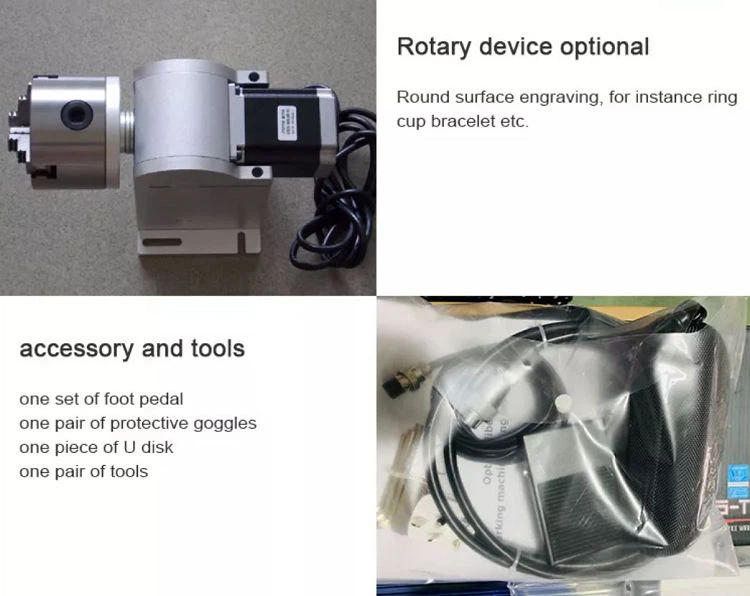

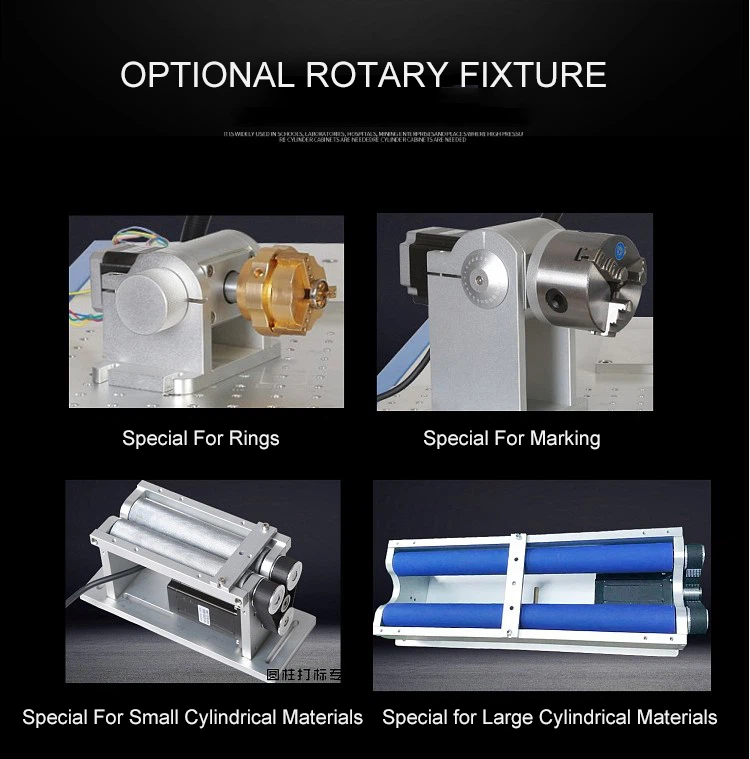

Optional Accessories

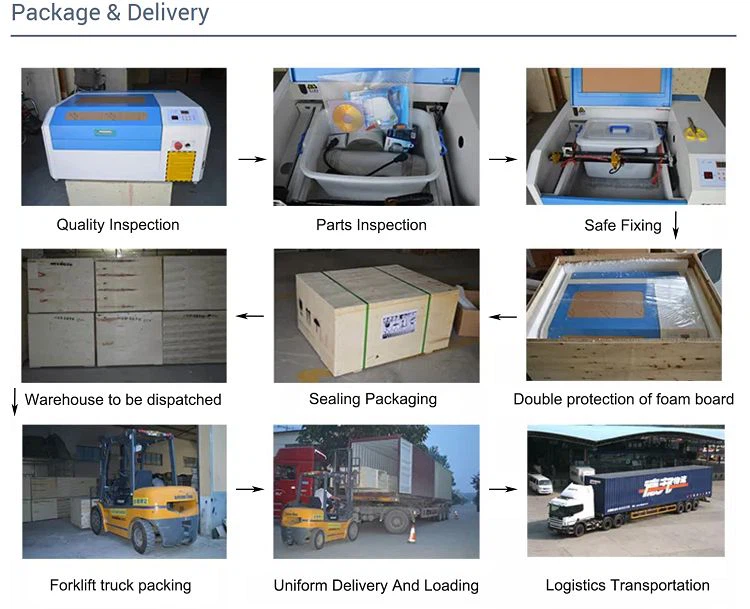

Packaging Process

Certifications

Hot Tags: split optical fiber marking machine, China split optical fiber marking machine manufacturers, suppliers, factory, Laser Engraving Machine for Tumblers, Mini Fiber Laser Marking Machine, Autofocus Fiber Laser Engraving Machine, RF Tube CO2 Marking Machine, CO2 Flying Marking Machine, 20w fiber laser marking machine

Compositions and Package

Main Accessories

FAQ

About the Laser

What materials can I cut or engrave with a CO2 laser?

CO2 laser machine can cut, engrave, mark a wide range of non-metal and organic materials, such as acrylics, woods, plywood, MDF, paper, cardboard, fabrics, leather, glass, stone, ceramics, and more.

What materials can I cut or engrave with a Fiber laser?

Fiber Laser can cut, engrave, mark on metals, such as steel, stainless steel, aluminum, brass, copper, silver, gold, and on some non-metal polymers, wood, fabric.

Shipping

How is the machine packaged?

Laser equipment is shipped in a wooden box with Styrofoam to protect fragile parts

How long does it take to ship by air?

After we receive the order, send the machine to one of the main DHL, FEDEX and TNT offices in China. Smaller machines are shipped by courier service. Typically, it takes 10 to 14 days.

How long does it take to ship by sea?

Larger machines are shipped by sea. Usually, it takes 6 to 10 weeks. We can help you arrange delivery directly to your location.

Customer Support

Is there a warranty?

Manufacturers extend the warranty on their devices to 18 months and replace parts at the factory purchase price.