Facing the challenge of welding highly reflective metals? Traditional techniques fall short.

Red-blue hybrid laser welding breaks through barriers with innovative dual-spectrum technology, redefining welding standards!

**Technical Advantages: Tackling Core Challenges**

• **Exceptional Compatibility**: Masterfully welds highly reflective metals like copper and aluminum—even copper-aluminum dissimilar materials. Boosts efficiency by 60% for applications like new energy battery tabs and motor windings!

• **Superior Stability**: Blue laser precisely suppresses spatter and porosity, while red laser ensures deep penetration and robust fusion. Achieves secure, void-free welds with yield rates up to 99%!

• **High Efficiency & Energy Savings**: Synergistic energy utilization reduces consumption by 30%, accelerates processing, and significantly cuts costs!

**Broad Industry Adaptability**

• **New Energy**: Ideal for power battery modules and PV ribbon welding—delivering reliability for green energy production.

• **Electronics Manufacturing**: Meets micron-level precision demands in semiconductor packaging and precision sensor welding.

• **Automotive**: Enables lightweight aluminum alloy component welding, advancing structural upgrades!

**Why Choose Us?**

• **Cutting-Edge Technology**: Continuous innovation through collaboration with global R&D leaders.

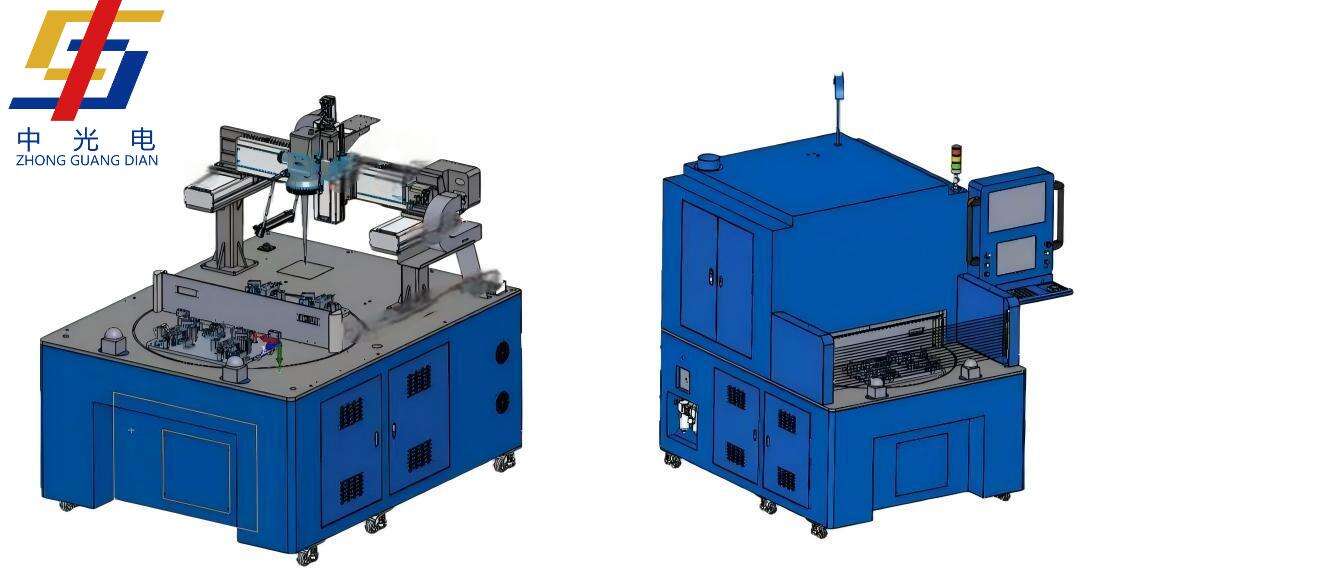

• **Customized Solutions**: Tailored systems for your specific materials and process requirements.

• **Worry-Free Support**: 24/7 technical assistance, maintenance, and training—all in one service.