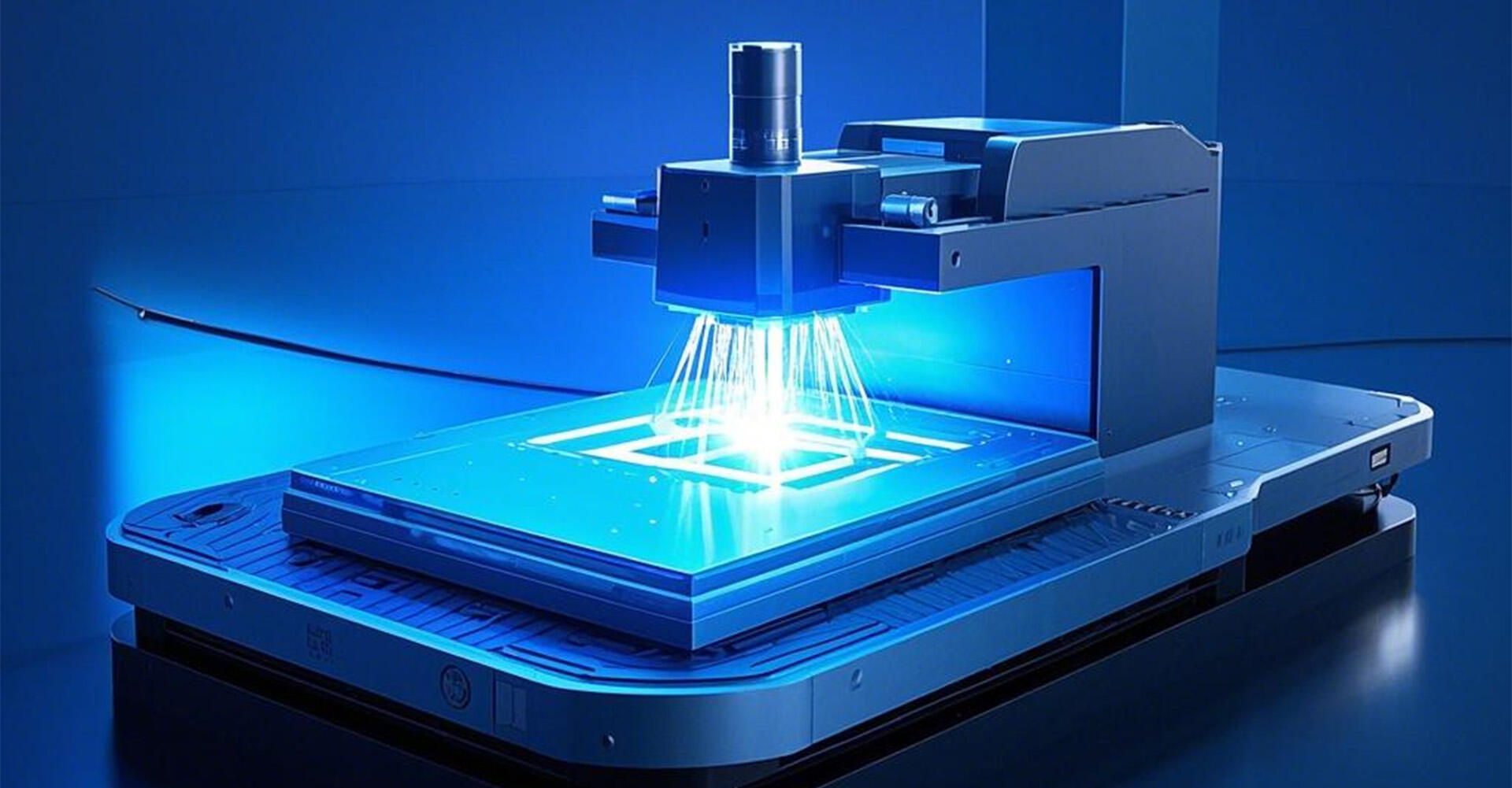

In the world of industrial laser applications, precision and efficiency are paramount. At Shandong ZhongGuangDian Optoelectronic Co., Ltd., we understand that optimal laser performance depends not only on the quality of the laser system itself but also on the supporting components that facilitate the cutting process. One such critical component is the serrated steel worktable—an often overlooked but essential element in metal sheet cutting operations. This article explores how serrated steel worktables significantly enhance the cutting process of metal sheets when integrated with high-quality laser systems.

Understanding the Role of Worktables in Laser Cutting

Laser cutting represents a technological advancement in material processing, offering unparalleled precision and speed. However, the effectiveness of any laser cutting machine depends greatly on its worktable—the surface that supports the material being processed. A standard flat worktable might seem sufficient, but when cutting metal sheets, particularly thin or reflective materials, challenges such as heat distortion, back reflections, and material movement can compromise results.

The serrated steel worktable addresses these challenges through its unique design featuring precisely engineered teeth or peaks that minimize surface contact with the metal sheet being cut. This reduced contact area provides multiple advantages that significantly improve the cutting process.

Key Benefits of Serrated Steel Worktables in Metal Sheet Cutting

Enhanced Heat Dissipation

During laser cutting, intense heat concentrates at the cutting point. With a flat worktable, heat can accumulate between the material and the surface, potentially causing thermal distortion or even damage to the finished product. The serrated design allows air to circulate freely around the cutting area, dissipating heat more effectively and maintaining the structural integrity of the metal sheet.

Minimized Back Reflection

When cutting reflective metals such as aluminum or stainless steel, laser beams can bounce back toward the laser source, potentially causing damage to optical components. Serrated worktables reduce this risk by minimizing the flat surface area from which reflections can occur, thereby protecting your valuable laser equipment.

Improved Cutting Precision

The raised points of a serrated worktable securely hold the metal sheet in position during cutting operations. This prevents unintended movement or vibration that could compromise cutting accuracy, ensuring clean edges and precise dimensions in the final product.

Reduced Contamination and Adhesion

Laser cutting generates debris, dross, and spatter that can adhere to both the workpiece and the worktable. The open design of serrated worktables allows debris to fall through rather than accumulate on the surface, resulting in cleaner cuts and reducing maintenance requirements.

Versatility Across Material Thicknesses

Serrated steel worktables accommodate various metal sheet thicknesses effectively. The spacing and height of the serrations can be optimized for different applications, making them suitable for everything from thin foils to thicker plates.

Integrating Serrated Worktables with ZhongGuangDian Laser Systems

At ZhongGuangDian Optoelectronic, we recognize that superior laser cutting results from the harmonious integration of all system components. Our laser marking machines and cutting systems are designed to work seamlessly with specialized accessories like serrated steel worktables. When you choose our equipment, you benefit from:

Proven Compatibility: Our technical team has extensive experience configuring laser systems with appropriate worktables for specific applications, ensuring optimal performance.

Quality Assurance: Just like our laser machines, which undergo rigorous testing before leaving our facility, we recommend worktables manufactured to the highest standards for durability and precision.

Customization Options: Understanding that each cutting application has unique requirements, we offer customized serrated worktable solutions tailored to your specific needs regarding serration pattern, spacing, and material composition.

Maintenance Considerations for Long-Term Performance

To maintain the effectiveness of your serrated steel worktable, regular maintenance is essential. Periodically remove accumulated debris from between the serrations, inspect for wear or damage, and ensure proper alignment with your laser cutting system. At ZhongGuangDian, we provide comprehensive guidance on maintaining all components of your laser system, including worktables, to ensure consistent performance over time.

Conclusion: Elevating Your Metal Sheet Cutting Capabilities

The serrated steel worktable represents a simple yet profoundly effective solution for optimizing the laser cutting process of metal sheets. By addressing critical challenges such as heat management, reflection control, and material stability, this specialized component significantly enhances both the quality and efficiency of your cutting operations.

At Shandong ZhongGuangDian Optoelectronic Co., Ltd., we combine over a decade of laser industry experience with a commitment to providing complete solutions that address every aspect of the cutting process. Our laser machines, complemented by accessories like serrated steel worktables, deliver the reliability, precision, and value that have earned recognition from customers worldwide.

We invite you to contact us to discuss how our laser solutions, including optimized worktable configurations, can enhance your metal sheet cutting applications. Take advantage of our free proofing service to experience the difference that properly integrated equipment can make in your operations.